I use the following headers and sockets for the ESP32, I buy them by the strip.

To add the components to the PCB, my recommendation is to start with all the passive components like resistors, capacitors and then the active transistors, MOSFET’s (not the main NFET’s

M1, M2), diodes and the voltage regulators U9 and U12. Do not install the

relay and the snubber circuit yet. What I then would do is to connect a Lab

Power Supply with a setting of 12V and 50mA to the DC input of the board. If it

powers-up without getting into current limitation, you will probably not have

any shorted rails to ground, and can proceed to test the +12, +9 and +5 supply

voltages. If they check-out, you can add the ICL7660 and test the -5V rail.

After that, you can add the REF5040 and check the presence of 4.096V. If

that also checks-out, you can add the trimmers, connector strips, DAC, ADC,

MOSFET switches (U14, U15), all the Opamps and finally, the main relay and

snubber circuit. Basically, everything except placing the ESP32 module in its socket, and

soldering the main NFET’s (M1, M2) and the LM35.

Obtaining the correct ESP32 variation

There are many, many variations of the ESP32 board. I'm using a version that is smaller in width and shorter in length. This is my preferred version of the ESP32, because it fits prototype boards. Most of the others are too wide and you have to connect two prototype boards next to each other to make the ESP board fit.

The version I'm using is also called the ESP32 DEVKIT V1 from DOIT. If you Google this, you will most likely find them. However, there is more to watch out for.

This board only has 30 pins, and the pin rows are about 25mm apart, which is why it will fit in a single prototype board. To make absolutely sure you have the correct version, you also need to look at the available pins on the board. The most important thing to look for are the pins are either end of the board. They must match the picture below.

Even then, there could be two other issues that I describe in a section further below. The board above has the blocking diode installed, visible just below the voltage regulator.

The other recommended ESP32 board is the VROOM 4MB DEVKIT V1.

However, I have found that

there are slight variations or differences for two components on various

sources for this board. One is the capacitor that should ensure a reset after a download of new firmware. On one of my boards, this capacitor was there, but

not well soldered to the chassis part of the USB-mini. On another one, there

was no diode to block the incoming 5V through the USB, and the VIN supplied

to pin 1 of the board. Having no diode but a 0R resistor means that the VIN

supply will back-feed 5V into the USB port of your PC. Not recommended!

To avoid having to mess with the ESP board and 0402 size parts, we have made provisions on the DL PCB to help fix these two issues.

Verify that the ESP32 module has a 1uF 0402 capacitor most

likely connected to the solder pad of the EN button. It may be soldered at a

45-degree angle, see the left blue arrow. If the capacitor is not installed, you need to install C44 on the PCB. (in the schematic C44 has a red cross through the part, to avoid placing this part when not needed)

Also make sure that there is a diode

installed and not a 0 Ohm 0402 resistor (marked 000) as you see here on the board. See the

middle blue arrow below for the location. The picture of the ESP32 further up in the Blog does have a diode, which can be easily identified.

If there is a 0

Ohm resistor on the board, you need to remove or not install R53 and install

D10 on the main PCB. See the schematic below. (in the schematic D10 has a red cross through the part, to avoid placing this part when not needed)

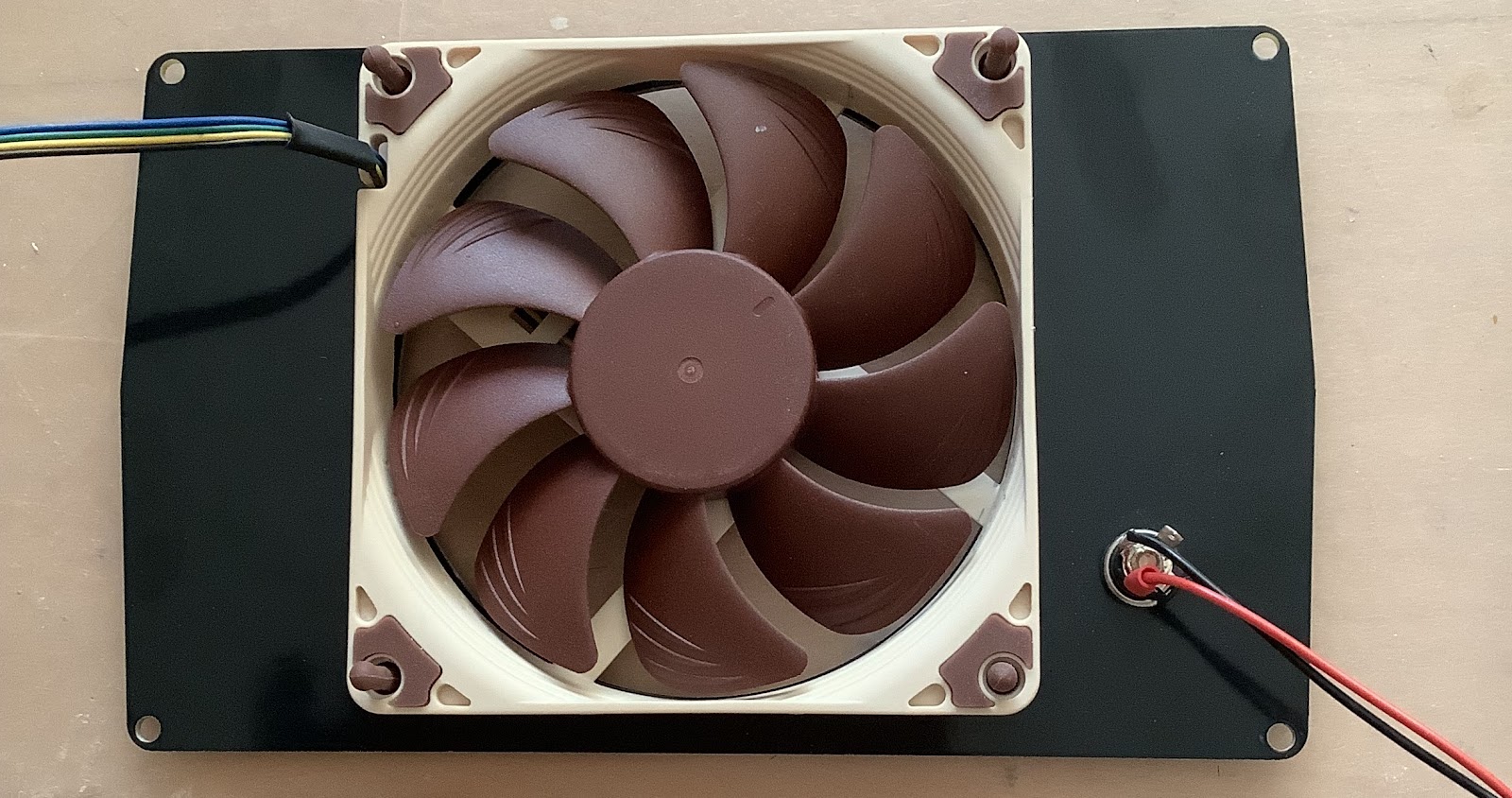

The Back Panel

At this moment in the build process, it will help to mount the fan on the

back panel so you can use it to double check the space between that fan and the second heatsink/fan combination that will be mounted on the bottom shell later.

The back panel fan will be mounted using the flexible silicon

mounts that come with the fan.

To help the installation by pulling on these flexible thingies, it is helpful to first counter sink

the 4 holes in the PCB on either side so the silicon will more easily slide into

position when you pull them in.

Note the position of the fan on the back panel, and

where the wires need to come out (top left).

The four wires from the fan come standard with a pretty stiff heat-shrink tube. That's too stiff to my liking, so I cut it off, exposing the four wires.

Modifying the enclosure

The bottom shell of TEKO AUS33.5 enclosure needs to be

modified so we can mount a fan on the bottom to suck fresh air directly into the heatsink

fins inside the enclosure. The fan mounted on the back panel will suck the hot

air away from the heatsink to the outside of the enclosure.

A number of holes need to be drilled in the bottom

shell to get enough airflow to the heatsink. I used Excel to create a raster

for the 6mm holes. The picture shows an earlier position of the fan, I later

moved it further down and added another number of extra holes.

To feed plenty of fresh air from the bottom of the

enclosure to the fan, we need to mount 4 feet that are about 1cm in height to

lift the instrument from the shelf or desk to create the space.

The bottom fan needs to be mounted in the middle of

the enclosure, and the mounting holes 25mm away from the back edge of the bottom shell, to make

room for the fan that is mounted on the back panel. Before you drill the holes,

use the back panel with the fan mounted on it to double check the space you

need. The minimum space between the two fans would be 2mm.

The bottom fan and heatsink

The bottom fan will be mounted on the shell by four 30mm

long M3 screws. Because of the plastic, and the two hole positions in the

ventilation area, I recommend you put M3 or M4 rings on the bottom and on the

inside of the plastic shell. Use a normal (flat) M3 nut to tighten the four screws to

the enclosure while making sure that the fan will easily fit. After the fan is

positioned on the four mounting screws, use an isolated M4 ring (teflon?) on top of the fan

before you mount the brackets holding the heatsink.

The heatsink will be mounted about 6mm above the

bottom fan by two strips of a 90 degree angle 15x15mm piece of aluminum. These

strips can be found in your local hardware store and probably come in a length

of 1mtr. Use a metal hacksaw to cut two pieces with a length of 90mm, which is

the same as the size of the fan. Drill two holes of 3mm each 15mm from each end,

that will hold the self-tapping screws mounting the bracket to the heatsink.

I used very short 3mm self-tapping screws to mount the

angle pieces to the heatsink. I also drilled the hole through the second flange of the

heatsink, to make room for the tip of the screw, so it does not bend the thin flanges.

Drill two more holes in the other flank of the L-shape brackets that are 81 mm

apart, so the screws holding the fan to the bottom of the enclosure will go

through these holes. Make sure that these holes are spaced such that when the L-strips are mounted on the heatsink, the holes of the fan will pass through the four 30mm long M3

screws.

Because the heatsink can get very hot, I used four 3mm

insulating rings of the type that are used to mount TO220 type devices isolated to a heat sink. For us they also

serve to electrically isolate the screws from the potential of the heatsink,

that can be up to 100V DC.

You’ll need a fifth one to isolate the LM35 from the heatsink later. These rings should fit the holes of the brackets, if not, drill the holes a bit larger to 3.5-4.0mm to create some wriggle room. I then used a Teflon ring on top of the insulators and used self-locking M3 nuts to loosely secure the heatsink, so you don’t need to tighten the nuts too much and put too much pressure on the plastic frame of the fan. You want to minimize the transfer of the mechanical vibration from the fan to the enclosure. It should be a fairly loose fit.

The thermal paste you see in the pictures is because I took my instrument apart to make these instructions and the pictures after I finished my build.

Mounting the Main NFET’s and the LM35

Before you mount the heatsink on top of the fan, you need to create

three M3 tapped holes in the heatsink to mount the two NFET’s and the LM35 temperature

sensor. If you don’t have a good quality and sharp M3 tapping set and the right

size drill (2.5mm), you can also use 3mm self-tapping screws. In that case it is

even more important that you counter-sink these holes well after drilling, so the aluminum

material does not come-up and push the devices up from the heatsink when you fasten the screws. If you use

the M3 taps, lubricate the drill and the taps well and clean the taps and

lubricate them regularly while you are tapping, to make sure that the threads

are not damaged. The NFET’s and the LM35 will need to be tightened to the heatsink well, to get

the maximum heat transfer, so the threats need to be well made.

I created M3 threaded holes for the two NFET’s 23mm

from the back-end of the heatsink, 33.5mm apart, and each about 23mm from the edge of

the heatsink.

The LM35 goes in the middle of the heatsink and 27mm down from the back. Countersink the holes and make sure everything is flat. Use a fine file or sandpaper with a stiff support if needed.

The other four holes you see are from previous mounting positions and are no longer used.

The front of the main PCB will be supported by two extenders

towards the front of the enclosure. I used two 30mm long M3 extenders screwed

together. You can use any length parts, as long as they are 60mm in total. The height can be further adjusted when the PCB is mounted. The position of

the holes in the bottom enclosure for these supports is best determined when the

PCB with the NFET’s and the LM35 is mounted on the heatsink.

As you can see from the picture below, the bottom fan is

positioned such that the wires come out at the left-hand side. The open side of

the fan must be facing the bottom of the enclosure so it sucks the air into the

enclosure.

Because the four wires for the fans have a shrink-wrap tube, they are too stiff to my liking, so I took the tubing off.

The NFET’s and the LM35 will be

mounted flat on the heatsink. The main PCB needs to be mounted as high as possible

away from the heatsink, to minimize heat transfer. With earlier

prototypes, I found that there is a surprising amount of heat transferred

through the NFET leads to the PCB. Keeping the legs long helps.

The challenge is to move the body of the NFET's as far away

from the PCB as possible, to again reduce the heat transfer by way of the

leads, and also the heatsink heating the bottom of the PCB. We also need to create

space away from the PCB to mount the two smaller TO220 heat sinks on top of the NFET's without them

touching the PCB. The place where you bend the leads of the NFET's upwards is

critical to accomplish this. I bend the leads of the NFET's after about

6mm from the case with 90 degrees (not too sharp!) upwards.

You can position the three devices loosely with a

screw using the M3 holes you created earlier, and then position the PCB on top

of them, with the leads protruding through the holes in the PCB. At this

moment, you can use the two mounting extenders to support the other end of the PCB so

it is about horizontal, or use something else to keep the PCB horizontal and stable. I also

used two spacers of 8mm to support the PCB near the NFET’s so you can position

the PCB horizontally in order to solder the leads, and keep them the right amount away from the PCB. Make

sure that the PCB is positioned high enough such that the NFET leads only just protrude 1-2mm

through the PCB holes to allow for proper soldering. The LM35 leads are a bit longer, so that’s OK. I suggest that at first you only solder only the middle leads at this moment. Be careful not to drop the

other end of the PCB and bend the NFET leads.

Once you are happy and double checked the position of

the PCB and the three devices, you can mark the position of the two front supports in position on the bottom shelf and then remove the three screws holding the three devices and remove the two extra 8mm standoffs.

You can now finish the mounting of the two

front supports by drilling the holes. I suggest that you use 3.5 or 4mm rings on both sides of the plastic for support. After you have secured the bottom portions of the extender to the enclosure, you can roughly adjust their total height by the second extender.

Before you finally mount everything again, apply heat paste to the NFET positions on the heatsink and use an insulated silicon pad with an insulator ring for the LM35. Loosely tighten the 3 screws again and use an Ohmmeter to make sure that the LM35 tab is insulated from the heatsink, because the NFET’s are not, and their pads will connect to the DUT voltage of up to more than 100V to the heatsink.

When everything is in position, you can tighten the screw for the LM35 and again check that the tab is still isolated. Unscrew the two NFET’s screws again and now add the extra TO220 heatsinks on top of them, using plenty of heat transfer paste.

Make sure that the heatsinks do not touch the PCB. You

can now carefully tighten the screws for the NFET’s.

After that, you can do a final adjustment of the two

front supports so that the PCB is horizontally mounted inside the enclosure. When that is done, re-heat the middle pins of the three devices, to let the stress out, and then solder the other pins. Use plenty of solder for the NFET leads, they will get stressed by the developing heat (up to 100 degrees C).

Preparing for a first power-on

After you have finished the above steps, we can start

to power-up the board again and verify some of the vital signs.

You only need to add the 12V DC power to the

board, but I recommend you use a Lab supply initially with a current setting of 100mA. If there is no large current, indicating a short or another issue, you can now switch to the 12V DC wall wart.

Do not install the ESP32 in its socket at this moment until you have verified the power rails.

Verifying the Power Rails

You can now

verify all the power rail voltages:

·

DC

Input 12...15V at J4

·

+12...15V

at pin 1 U9 (LM7809)

·

+9V

at pin at pin 3 of U9

·

+5V

at pin 3 of U12 (LM7805)

·

-5V

at left side of C31 or pin 5 of U5 (ICL7660)

·

+4.096V

on either side of R60

When that

is OK and within specifications, you can go to the next step, but first disconnect the 12V DC input again.

Adjusting the OLED display in position on the front panel

For this step we need to install the ESP32 module on

the PCB and load the ESP32_OLED_Test_V1.ino firmware, located on the Github site.

Do not apply the main 12V at this moment, it is not

needed for this step.

The OLED module connects to J6 on the PCB. The module

comes with flying leads that each have their own 1-pin connector. I recommend you

change these single connectors to a 7-pin connector so you can’t make mistakes

with the order, and it’s a lot tidier and easier to remove and install.

You can connect your PC to either the mini-USB of the ESP32

module, or start to use the mini-USB to USB-C adapter. When you have made the

connection, the red power LED on the ESP32 module should light-up and your PC probably will give a signal that a new device is connected.

I’m assuming that you already installed the Arduino

IDE. If not, you need to do that now. There are plenty of instructions on the

internet to do that successfully. You must also install support for the ESP32 and you can use Google to find the instructions. I was using IDE V2.3.2 and now the just available V2.3.3. The Arduino IDE is needed

to load the firmware for the ESP32 module. Locate the ESP32_OLED_Test_V1.ino on

the GitHub and download it to your PC. Save it in a new directory called “VB

Dynamic DC Load” in the Arduino directory on your PC, it is most likely located

in your Documents directory.

After you saved it there, use the Arduino IDE to

locate the file and load it into the IDE.

After loading the firmware, in Tools select Board and

search for the DOIT ESP32 DEVKIT V1 in the esp32 branch. That’s the ESP module

we use, and the firmware will most likely only work with that module.

Under Tools, select the connected COM port to establish communication to the ESP32.

Compile and download the firmware and see if it gives

you any errors.

If there are, you need to figure out what the problem

is. There are too many possibilities to help you from here.

The OLDED display board is just lying on your desk and that's OK. Install the connector from the OLED display to J6 on the main PCB, and position the module so you can see the screen and the white connector on the back is on the right-hand side of the display. When done, you can now connect the main 12V

power again, because it is needed to power the OLED. You need to press the EN button on the ESP32 module to force a reboot after you supplied the 12V. When successful, you should first

see a splash screen with the version number for a few seconds and then see a white square on the

OLED screen because all pixels are lit. Congratulations if you got this far!

The text of the splash screen will show the proper orientation of the OLED display. You could change the orientation

of the display in this test code and repeat that later in the firmware, but if

you keep to the instructions, and have the white connector on the right-hand side of the OLED module,

you should be good to go.

You can now proceed to mount the OLED display in position on the

Front Panel.

Mounting the OLED display on the Front Panel

To prepare for the mounting of the OLED display in

position on the back of the Front Panel, we need to change the mounting

hardware that came with the display.

During all these operations, keep the screen protector

foil on, or apply it again. It will prevent you from scratching or smutching

the glass. Use gloves when appropriate.

Remove the four M2 screws and standoffs. Keep the four screws, but we will not need the standoffs. You need eight extra M2 nuts and four M2

washers to prepare to mount the contraption on the font panel.

Add an M2 nut to the

M2 screws. Stick them through the hole of the board, and add an M2 washer and then

another M2 nut. Tighten loosely. The M2 washer is needed to create some extra

space between the glass of the OLED and the Front Panel, so don’t skip it. You

may otherwise break the OLED display. Do this for all the 4 holes of the OLED

board so it looks like the pictures below. The four nuts will be glued to the PCB pads.

You can now position the OLED board to the back of the

Front Panel and check the fit. It should slide on the four nuts, not the glass.

Apply the 12V main power again and do a reset of the

ESP32 (press EN) to verify the orientation of the text from the splash screen

and then see if you can position the white rectangle in the center of the square of the front panel.

You can now peel the protective cover of the glass, because that may be difficult or even impossible later on. I strongly suggest you use gloves and avoid any finger prints or worse, glue getting on the

glass.

Before you do the next steps, I suggest you

practice the next moves once or twice to make sure you can position the OLED

properly without tangling the wires or moving the OLED display that you just

glued in position. If you are not happy using Superglue, then use normal glue

that you can still move a bit, but you then should tape the two together and

let it dry for a few hours.

I use Super Glue paste, not the liquid to avoid dripping the goo all over the place.

With the OLED module powered and showing the white square,

hold the OLED board with the display side up in one hand, with the white connector on the back to the

right-hand side and add a drop or two of (Super)glue on each of the 4 nuts that will connect to

the solder pads on the back of the Front Panel.

With your other hand, pick-up the front panel and position and hold it just above the OLED screen

with the silkscreen text from the front panel up and make sure the white LED rectangle square is in the middle of the square hole in the front panel. When

satisfied, slowly lower the front panel and press the two together and let the (Super) glue dry.

After a few seconds with Superglue, you can carefully turn the Front Panel

together with the OLED board face down so the OLED stays in position and you can let it dry a bit more.

If you used

normal glue, you then need to secure the OLED in position with sticky tape so

it will not move while you let it dry for several hours.

Turn off the power and disconnect the USB connection

to the ESP32.

Wait with the next steps until you are sure the OLED

display glue is dry! Give it enough time to dry or you will regret it.

Loading the Dynamic DC Load firmware

The firmware for the Dynamic Load is located on the GitHub

site and needs to be downloaded before you can load it into the Arduino IDE.

The firmware is needed to operate the instrument, and at power-up will make

sure everything starts in a known and safe state.

The firmware is in a zip file with the name of the version number. You need to unzip the zip file and put the 6 files in a new directory that must have the same name as the zip file, and create that directory in the ../Documents/Arduino/VB Dynamic DC Load directory you created earlier.

The firmware consists of 6 different files that the

IDE will stitch together to create the firmware during the compile, link and then download

process.

Load the file into the IDE and compile & download

it to the ESP32 module. You don’t need to turn on the 12V just yet. Just make sure

it finishes without errors. The first time can take a several minutes so be patient

and just look at the bottom screen of the IDE to see what is going on.

First firmware turn-on

Do not supply the 12V yet and also do connect the two fans to the PCB at this moment yet. Position the front panel with the OLED connected to the main board such that you can easily see the display. The front panel does not need to be mounted to the enclosure yet, but you could temporarily do that.

When there are

no compile or download errors, the firmware is loaded and started, and with the

red power LED on the ESP32 module already on, the blue LED now starts to flash.

If that is the case, then congratulations are in place again. Well done!

With the

USB power applied, and when you now supply the 12V main power, the ESP32 is not

getting a reset. You need to do a manual reset (press the EN button) again so the firmware

is restarted, the OLED now becomes operational and after the splash screen with the version number, you should see the following start

screen.

Great if you are this far! Don't worry about the "negative" or "invalid" warning in red for the voltage. That is because nothing is connected yet and the inputs are floating. The temperature reading for the heatsink in the lower right corner should be OK though.

Connecting

the fans

Turn off

the 12V and remove the USB connector. If you still use the Lab Supply, raise

the current to 350mA. You can now connect the two fans to the PCB and go to the next step.

Boot

sequence

When you

apply the 12V main power, the red power LED on the ESP32 module will switch on, and both

fans will start to run at full speed. After about 2 seconds, the splash screen appears

and the blue LED on the ESP32 module will start to flash. The flashing is an indication for the execution of the firmware main loop. The splash screen

makes place for the initial screen display and the fans will be turned off. That actually completes the boot sequence. The instrument is now ready to make measurements and accept commands.

If you got

this far again, great!

The

front panel

It is now

time to finish the front panel installation, and connect the remaining leads

and parts to make the unit fully functional.

In the

picture below you can see my wiring on the back of the front panel.

To connect

to the rotary encoder, I used a ready-made and assembled wire-harness that I

purchased in different pin sizes. Here I’m using a 5-pin version. On the rotary

encoder itself, I bridged the middle of the 3-pin connector which is GND to one of the two switch pins. The VCC pin of the connector is not used. It is there in case you

have a rotary encoder with a debounce circuit that needs power. The firmware works well enough with the rotary encoder without hardware decoding support.

The main

power leads for the DUT are heavy duty and I used so called car connectors to make it easy

to mount them. Make sure they can handle 10A.

It’s a

little hard to see, but there is a 10nF capacitor directly soldered on the Current

Monitor BNC, to take care of a nasty glitch caused by the induction of the cables.

For the

main DUT and sense inputs, I used these 4mm Banana binding posts. They have the correct

19mm distance and you can use wires as well.

The wiring

of the sense switch is quite simple. I connected leads between the main Banana terminals and the sense terminals with solder lugs and used two wires connected to the center pin of the switch to go to J3 on the PCB.

The power switch is in between the plus lead coming from the DC jack on the back panel and the positive connection of J4 on the main board. The ground lead from the DC jack goes directly to J4.

I used

2-pin wire harnesses for the Current Monitor and the Transient Input connectors,

and used these BNC connectors:

The main

power switch and the USB adapter are not showing in the picture.

To make

sure you don’t pull out the USB-micro to USB-C adapter from the ESP32 socket, I

positioned the adapter with everything mounted, and used a tie-wrap flush to

the front panel to secure it. To make sure it stays in position, I used some

glue to fix the tie-wrap into position.

With the USC-micro to USB-C adapter connected to the ESP32, you may need to adjust the front supports of the main PCB so the adapter easily fits the hole in the front panel.When that is done, you can put the front panel and all the wires to the main PCB in position, and secure the front panel with the two bottom screws to the enclosure. Do not install the top cover just yet.

With everything thus far installed, you should have a fully working instrument that should look like

this:

You are now

ready to move on to the Calibration & Verification section.

Calibration & Verification

Remove the top cover of the enclosure. You need access to the trimmers and test points.

Initial step

Make sure you have the latest firmware version installed that is available on the GitHub.

To start the

full procedure again after an earlier procedure, you need to revert some of the

calibration factors in the firmware back to the original value. These constants

are located in the calibration section in tab ESP32_V4_xx.ino of the firmware in the Arduino IDE starting at around line 54.

·

double const shuntVcalib = 1.0; // optional

·

double const dutVcalib = 1.0;

·

double const cvCalFactor = 1.0;

Set these values to 1.0 if not already and recompile and load the firmware.

Calibrate the OLED voltage display

1. Set a Power Supply to 2.50V, or use a

voltage reference, connect it to the main terminals of the Dynamic Load (DL). Use a DMM to verify the actual voltage.

2. Set the remote sense switch to off.

3. Make sure the NFET’s are OFF so there is

no current flowing.

4. Note the OLED display for Voltage and adjust RV1 on the PCB so the OLED shows

the same voltage or as close as you can get it. (due to the averaging and the resolution, take your time)

5. Use a Power Supply to raise the voltage

to just below 100V or as high as your supply supports (stay below 105V), and verify using a DMM.

6. The difference between the DMM

measurement and what the OLED shows should be less than +/-0.5%. If it is more,

you can activate the optional calibration factor in the firmware to apply a correction.

7. Calculate the difference with the DMM

and the OLED voltage and use that as a factor below.

·

double const dutVcalib = 1.0;

The calibration constants are located in the calibration section in tab ESP32_V_4_xx.ino of the firmware starting around line 54.

8. Recompile the firmware to apply the

calibration, and run this calibration section again to verify.

Verify the sense switch operation

1. Set the Power Supply to 30V and a current of at least 1.5A. Connect sense leads from the DL sense inputs to the Power

Supply. Directly connect them at the Power Supply connections.

2. Switch the sense switch to on and

verify that the DUT voltage is the same in both on and off settings.

3. Turn the DL input ON with a short press

of the decoder button, and check that there is no current flowing yet. Adjust

the rotary encoder of the DL load such there is at least 1A flowing as a load.

4. Alternate the sense switch in both

positions to show the effect of the external sense input that will compensate the voltage reading for higher currents flowing through the main leads, that will cause a loss and therefore a voltage

drop. If you switch to higher currents, the effect will even be larger.

Current calibration for the DAC

1. Set the Power Supply for a voltage of

10.0V

2. Connect a DMM to the DAC test point and a GND test point on

the main PCB and use the rotary encoder to get a reading closest to 400mV on the DMM - let the system

warm up for a few minutes and readjust if needed.

3. Adjust RV2 on the main PCB to get a current of 1.000A on

the power supply or measure the current with a DMM. Note that the current on

the OLED display itself will not be accurate yet, it still needs a calibration.

Verify the DAC-ADC and the Power Section

accuracy

1. Measure the voltage at the DUT_I test

point on the main PCB -- it should be between 396 and 404mV which is an accuracy of +/- 1%.

2. Store the error in DUT_Current.

·

double const DUTCurrent =

400.00 - your reading in mV; (it is not used however)

Calibrate the OLED display to show the

correct current value

1. Make sure that the shuntVcalib constant in the firmware has a value of 1.0.

2. If not, set it to 1.0 and re-compile and load the firmware with that factor.

3. In the CC mode, with the load ON, set

the current with the encoder such that the Power Supply shows a current of 3.00A, or use a DMM in current mode to measure the current.

4. Note the current value on the OLED

display and divide the Power Supply or DMM reading by that of the OLED value.

5. Enter that result (it will be around

2.5) in calibration constant shuntVcalib and re-compile the firmware to activate it.

6. Verify that the OLED current now is

virtually the same as the Power Supply or DMM current at different load values.

Calibrate the CV mode tripping voltage

1. Make sure that the calibration constant cvCalFactor in the

firmware has a value of 1.0.

2. If not, set it to 1.0 and re-compile and load the

firmware with that factor.

2. Use a Power Supply and apply a voltage

of 50.00V, set the maximum supply current to 100mA. (When the CV mode is

tripping, a Lab Power Supply will go into the CC mode, and will apply the full

current to keep the voltage the same. We want the current to be low, to keep

the temperature low during this calibration)

3. Activate the CV mode, the Set voltage

will be automatically set to 10% higher or 55.00V. Turn the DL to ON. There

should be no current flowing, if there is, raise the set voltage until there is

no current flowing.

4. Slowly dial down the Set voltage with the rotary encoder and

take note of the Set value when the tripping point happens. This is when current starts

to flow. You will have to raise the Set voltage about 0.5V higher in order to

turn the current flow back off. This is the normal hysteresis activity.

5. Calculate the deviation factor of the DUT voltage and the tripping point voltage and apply that

to the calibration constant cvCalFactor and recompile and load the firmware to make it effective. As an example,

with a tripping voltage of 52.50V, the deviation is 52.50/50.00=1.050000 and that

is the calibration factor that needs to be stored in the firmware.

7. After recompilation and loading, verify that the

cut-in voltage is now very close. (it is unlikely you

will get it exactly the same, but it should be within a few percent)

8. Try the CV mode now with a Power Supply

setting of 2.00V and verify that the tripping point is very close. You will have to dial-back the rotary encoder from 50V down to 2V, which, even with fast dialing, will take some time. You can also cycle through the modes by long-pressing the rotary encoder, until you are back at the CV mode, in which case the Set voltage is automatically set to 2V + 10%.

CV mode with a regulated (CV/CC) power supply

Note that with a Lab Power Supply as a DUT, the CV mode is a bit more difficult to use due to the rapid switch of the power supply from CV to CC at the DL tripping point. You need to carefully adjust the encoder to get to an actively controlled load.

CV mode with an unregulated supply

To better test the CV mode and get more familiar with it, you can use an (unregulated) power supply that does not have current fold-back or current limiting/regulation. A transformer with a (bridge) rectifier and an electrolyte filter capacitor will much better show the CV mode regulation in operation. This kind of DUT will clearly show the sagging DUT voltage as a result of the load.

CV mode with a battery

Basically any battery or cell will provide another DUT to get familiar with the CV operation. Be aware that some of these cell can deliver a lot of current. This is one of the reasons that in the firmware, the current limit in this mode is set to 4A, hopefully preventing injuries or fire-works. Because the battery or cell will to its utmost to keep the voltage stable, you can clearly see the effect of the current changes.