Although I have been using my 0-30V 0-1 or 3Amp power supplies for quite some time now, I have never been really happy with them. They are described in other posts on my forum.

The major design constaint, in my opinion, has to do with the poor scaling of the circuit. It is not possible to go much above 30Volt at the output, because the raw input voltage will become too large for the maximum supply voltage of the used Opamps. Also, the current shunt is too big, causing a significant voltage drop in the ground circuit at higher loads. Also not very good.

As I have shown in my forum post while trying to improve this design, a significant weakness of the design is that (deadly) transients can appear on the output when the main power is switched on and off. You need to go through some significant modifications to avoid this. Lastly, the reference voltage that is used for the voltage and current setting is simple, but not very quiet nor stable. This principle design is very popular and easy to build but dates back many years. It was designed with the 2N3055 as the pass transistor, which is notoriously slow. Lastly, it is not easy to modify this design to use digital controls, ie control the volt and current settings with a DAC.

I always wanted to build a supply myself, so after a lot of reading forum posts of designs, studying other designs DIY and commercial and several handbooks, I started to piece together what I wanted. BTW, an excellent reference is the "DC Power Supply Handbook" or Application Note 90B from Hewlett-Packard/Agilent Technologies. There are 3 versions of that App Note as far as I know. Google for it and you shall find. Figure 3 on page 19 of the B version shows the basic block diagram of the supply I want to build.

DISCLAIMER

I'm not a professional engineer, I'm a hobbyist. I do have an electronic education, but that formally ended in 1972. After I retired a number of years ago, I picked-up my old hobby and I have been learning ever since. I try to document what I'm doing for people that know as much as I do, or even less, that are trying to learn as well, so I try to keep it simple. I'm using simplistic terms and they may not always be totally correct and I won't go in the theory, nor will I explain everything I did. Please keep that in mind.

BTW, I did not design this Power Supply from scratch myself. It is a combination of various pieces I found over the last couple of years, and they are the result of much more qualified people. I only made some changes here and there or adjusted or modified something to suit my needs.

Design Goals

Before we dive in, I had set aside a couple of goals that I wanted this new supply to have, basically making a much improved version of the ones I already have (all described in other posts on this blog)

The first one was to eventually drive this supply with a micro controller. This would allow me to precisely set the voltage and current levels, but also combine the power supply with a new programmable DC Load and create a feed-back system for elaborate tests.

This requirement puts some constraints on the way the Voltage and Current are to be set. I also wanted to use a much better reference voltage, to make the supply as quiet as I could, without going to extremes. I can't really measure that anyway.

Yet another one was to make the analog and later digital controlling hardware as detached as possible from the power section. This allows me to use the same design with very different supply specifications. The reason is that I put my transformers in separate enclosures. Power transformers are expensive and bulky, and my bench space is precious and limited. The other power supplies I have follow the same principle. It allows me to switch raw supplies or upgrade transformers without rebuilding the complete power supply. The new basic controller architecture will allow me to go up to 100Volts or more if I want to, and 3, 5 or 10 Amps if needed.

The Basic Concept

To get started, let me explain the basic principle by using a simulator. I use LTspice.

Here is the basic concept:

The pass transistor, a TIP142 NPN Darlington transistor, is biased with a stable 10mA current. With this current applied, the transistor will be fully open, so the output voltage is the input voltage minus the drop of about 0.6V The bias is accomplished with V1 and I1. R3, the base resistor is needed to avoid oscillations, and needs to be as close as possible to the TIP142 transistor Base pin. The pass transistor is going to manage a raw power supply, V2, which is currently set to 10V.

The "Trick"

The "trick" to drive the TIP142 on and off is to actually "suck" the bias current away from the base. In this simulation example, that is accomplished by another voltage source, V3. Because we want a visual indication later on if the supply is in the Constant Voltage (CV) or Constant Current (CC) mode, we use an LED in series with a small current limiting resistor, R5. The voltage source V3 is simulating the Voltage setting circuit. In this case, we let the voltage step from 0V to -4V with a slow rise and fall time. Because the negative going voltage will source a current through the LED and R5, it will take something of the available constant current (10mA) away from the pass transistor, making it less conductive and hence limiting the output voltage.

The Floating auxiliary supplies

Note that for this circuit, all the controlling voltages are referenced to Vout+, which is tied to the ground level of the overall circuit. On the outside BNC connectors, this does not matter, because the negative output (Vout-) is the "ground" level to the outside world. So the negative output voltage, which will be the "zero" reference, is floating downwards. This construction is key to these kind of supplies and you really need to be able to wrap your mind around this before you can continue to follow and understand this architecture. If not clear, read the H-P app note I mentioned earlier.

So in essence, the auxiliary supplies for the controlling logic are floating on top (+5V) or below (-5V) the Vout+ supply, and this is accomplished by tying the ground of the auxiliary supplies to the Vout+ pole. Now you can probably already see why the raw supply can be 100V, because it does not matter for the controlling logic. It floats on whatever level of the raw voltage we select to use.

In any case, here is the result of the simulation:

The red trace is the result of V(set), the voltage source V3. The green trace is the output voltage, measured at the negative side of the output (Vout-) At about -2.7V of V3, the conductivity of the pass transistor is closing rapidly, and about 0.6V further down, the transistor is "closed", there is no output anymore. When Vset starts to rise again, the same happens in reverse. Look at this graph and the circuit until you really grasp what is going on.

Controlling the Constant Voltage Setting

The next step to control the above turn on/off process better is by using an Opamp that is more capable to open and close the transistor. By selecting an inverting Opamp, we get a positive going voltage setting resulting in a rising output voltage. When we apply the resulting output (Vout-) to the Opamp, we give the Opamp the feedback to get a closed loop system. I specifically selected the TL071IP Opamp, because it is available in a DIP and SOIC version, dual and single Opamps per package, has J-Fet inputs and is generally speaking a very good Opamp. There many others to choose from, in most cases you will not really see any benefits or changes.

Here is the LTsim schematic:

A few things to note. I have raised to raw supply to 35V. This gives the series pass transistor some headroom for a 30V supply output. The Power Supply itself is really a high gain amplifier. It needs a capacitor (C1) on the output for several reasons. This capacitor should be as small as possible. The inverting Opamp has a small capacitor (C2) in the feedback to limit oscillation, and this turns it into an integrator as well. This capacitor could also be applied across the feedback resistor R4, or in a combination. We'll get to that later. The feedback resistor R4 has a value that limits the output of the supply to 30V. The combination of the voltage setting and the feedback is "summed" at the inverting input of the Opamp.

This is the result of the simulation:

The green trace is the result of the Voltage setting source V3, which is now going from 0 to +5V. This results in an output voltage (red trace) rising with the input voltage smoothly to the maximum output of 30V, and back again.

If we were to use a potmeter connected between ground and +5V, instead of V3, we could set the output precisely in the range from 0 to +30V, which is what we want.

Note that the voltage we feed into the summing input of the Opamp to set the output voltage, has a direct relationship (5V in = 30V out or 1:6), so every change due to noise or instability of the input voltage will have a direct influence on the output. From now on I will refer to this voltage as the Reference Voltage.

The reason I selected +/- 5V for the auxiliary supply is to accommodate a DAC and ADC later on.

Note that the only component that needs to change if you use a different raw voltage, is the feedback resistor R4.

This is an important step if you want to make a supply scale-able and universal.

Adding the Current Limiter

The next logical step will be to add a way to control the amount of current the supply can deliver to the output. The easiest method is to include a small (shunt) resistor in the output connection, and measure the voltage across it. When the voltage level across the shunt has reached a certain value, we want to limit a further rise.

Here is the LTsim circuit with the current limiter added:

The second Opamp measures the voltage across the current shunt resistor through R9, and compares that with the current limiter voltage reference V5. The current shunt should be as small as possible to avoid adding an influence and to limit the heat developed into it with high currents.

The principle is the same as with the voltage setting. When there is too much current, the second Opamp will start to suck the bias current away from the series transistor, and that will lower the conductivity, resulting in a lower output.

Because the voltage drop over the shunt is very low with only a 10mA load (the 3K3 resistor), I used some formulas in LTsim to lower the voltage setting and the voltage output, so you can see the relationship.

The purple trace is the voltage setting. It still goes from 0-5V, but the trace level is divided by 100 as you can see in the label. The green trace is the current level voltage, going from 10mV towards ground. The power supply output is the red trace, divided by 600 to show the relationship. You can see that the output is going back in step with the current setting voltage all the way to 0V when the current limiter is active.

I already mentioned that the Reference Voltage is critical, and especially with the Current Limiter, which deals with milliVolts, this is even more critical. Another stability factor is the bias current level. When this fluctuates, the output cal fluctuate with it. Let's look at a simple circuit that will be an adequate constant current source.

The Bias Current Circuit

Here is the really simple circuit that will provide the bias current for the pass transistor.

A single transistor, two resistors and an LED is all that is needed. The LED is a red (3mm) version. The color can also be green, but stick to these two because of the voltage drop. With an emitter resistor (R1) of 220Ohm and a bias resistor (R2) of 5K6, you get a steady 8mA constant current at the collector. The type of transistor is not really important, I use a run of the mill 2N3906.

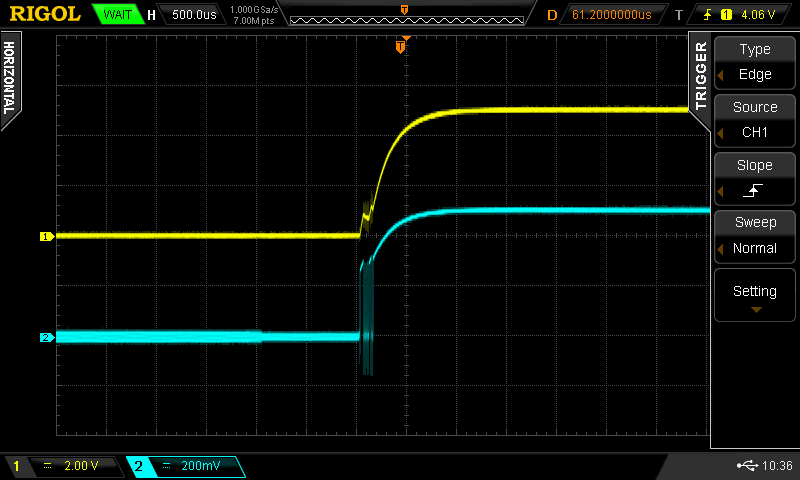

One important aspect of a power supply is the ability to switch it on and off with the main switch. You should never really do that, but as a minimum, there should be a form of protection, such that the supply does not harm your Device Under Test (DUT). Typically, when a supply is started up, the voltages for the various parts need to settle before regulation is stable. With this circuit, we can add a capacitor across the LED to delay the bias current for a few 100 milliseconds, so the other circuits have time to stabilize before the TIP142 gets turned on. I selected an electrolyte capacitor of 200uF. This will delay the turn on by approx. 1 second.

We will discuss the turn off protection later.

Main Power Off Protection

Just in case you switch off the Power Supply through the mains switch, or when there is a mains problem, you don't want the Power Supply to damage or destroy your DUT. You may have some expensive parts that your working with.

The turning off is a delicate and unstable process, due to the dwindling supplies. They may all act differently due to the load that the supply is feeding, and the capacitance reservoirs in the internal supply circuits. I have seen outputs of power supplies that shot op to several times the set output voltage, surely destroying delicate parts.

This supply was behaving rather well, but if you try long and hard enough, there will be situations where there is a large spike on the output. The following circuit makes sure that as soon as the main supply is decaying, the pass transistor is switched off, regardless of the state of the controlling logic. I spent quite some time finding and improving that circuit, and eventually settled on this:

I will show later that I use a small 9-0-9VAC transformer to create the +/- 5V auxiliary supply voltages. The AC voltage is rectified and fed to 5V regulators. These typically have a 2V drop out, so they will certainly regulate when the input voltage is above 7V. The rectified and buffered raw voltage is about 13V. This is simulated by V2, which is the input to the turn-off protection circuit.

The base of Q1 gets turned on when the voltage is that of the Zener diode (10V) plus the 0.6-0.8V of the Q1 junction, or at 10.8V. That turn off is amplified by Q2, which acts like a Schmitt-Trigger and further amplified by Q3. Q3 will turn on and start to sink the current from the bias circuit, turning the pass transistor fully off.

Here is the result. The green trace is the raw 13V supply. If that falls below 10.8V, the auxiliary supplies are still fully functioning, but Q1, Q2 and Q3 immediately sink the bias current away from the TIP142 to 0mA (the red trace) and so turn off the output.

I will continue in Part 2

http://www.paulvdiyblogs.net/2017/07/my-new-power-supply-design-part-2.html

.png)